You’re not alone! Mactec has been busy replacing outdated and inefficient pouching lines for several customers seeking to reduce package defects and improve operational efficiency. And of course, all machines include Mactec’s commitment to world class customer service.

Mactec offers compact vertical and horizontal pouching solutions with up to 99.9% efficiency. Our lineup of pouching machines is capable of packaging tablets, capsules, soft gels, liquids, medical devices and much more. All machines offer the choice of manual or automated filling systems.

Common Industries for Mactec’s Pouching Lines:

Key Features:

- Ease of use by a single operator

- Fast and easy installations – our machines require only electrical power and compressed air

- Ability to meet FDA standards with optional cleanroom configurations

- Short lead times on standardized machines get you in production within a few months

- In-house team of design engineers work with you and or your end-customer to design and engineer customized packaging solutions

- On-site service is only a phone call away with our team of technicians ready to assist

- All machines are designed, engineered, and manufactured in the USA out of Mactec’s NJ headquarters

When looking for pharmaceutical grade equipment that is suitable for smaller to medium sized production capabilities, look no further. Mactec’s equipment has been serving the 503B pharmacy market for well over a decade. When speaking to decision makers about why Mactec is their preferred equipment supplier, we hear answers such as:

- Machines run all day with little operator interaction required.

- Ease and ability to conduct tooling changeovers for different products or fill volumes in a matter of minutes.

- Small machine footprints and mobility make it easy to move around the facility when needed in different locations.

- Return on investment is significantly faster than other options in the marketplace.

Common 503B Pharmacy applications and equipment types include:

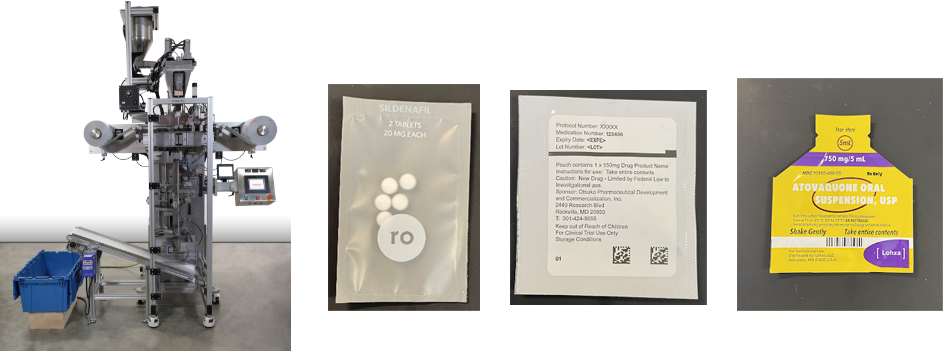

MT Vertical Pouching Series:

Capabilities include various solid and liquid dose applications. Common applications include packaging of powders, liquids, tablets, and capsules.

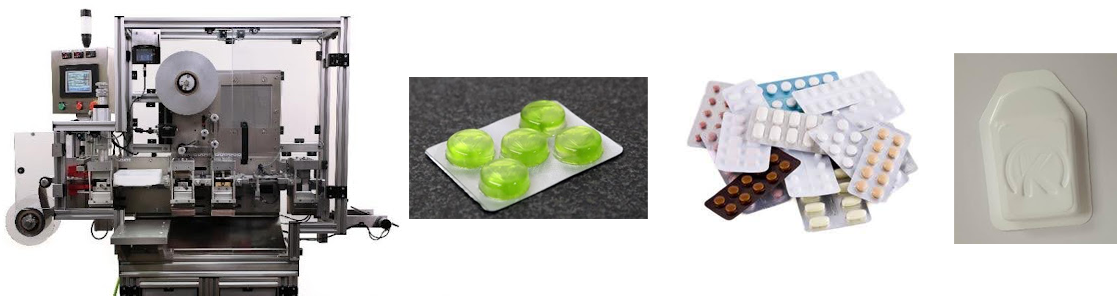

MT Horizontal Thermoforming Series for blister and pouch packaging

Capabilities include various solid dose, liquid dose, and medical device applications. Common applications include in-line forming, filling, and sealing of cups for liquid dose medicine.

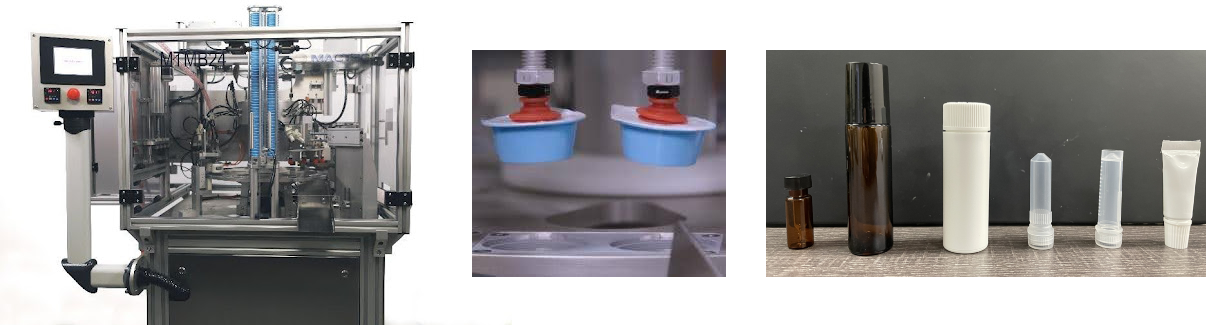

MT Rotary Filling and Sealing Series:

Capabilities include unit dose filling and sealing of cups, vials, tubes, and small bottles. Common applications include creams and liquid medicine.

Mactec recently completed two highly automated machines that work in conjunction to create “ready for use” packages in one step.

The first machine is a vertical pouching machine that fills two cavities with two different liquids. The second machine is a horizontal pouching machine that places the liquid filled pouch in its final package.

Users open the final pouch to remove the liquid filled pouches, then “burst” the seal between the two liquids, mixing the two liquids prior to dispensing the combined liquid.

Click here to see the machines in action.

Have a packaging need? We’ll help you solve it. Call us at 732-416-8525 or email us to speak to our experts today.

Happy Holidays from the Mactec team to you! Wishing for a happy and healthy holiday season filled with family, food, and laughter. We thank you for your business and support throughout 2022, and we are excited for what the New Year will bring!

#MactecPackaging #Goodbye2022 #packagingsolutions #newyear #happyholidays

Mactec is proud to announce the successful FAT of two MTMB-32 Monoblock vial filler/cappers. These units will ship soon to one of our customers where they will be placed alongside two of Mactec’s MT-150 blister packaging machines to produce components for a variety of testing kits. Both MTMB-32’s included some unique features: multiple presence detection systems, visual fill level inspection, air filtration systems, and multiple rejection protocols. Lots of features in such a mobile machine!

Congratulations to our customer and hats off to the Mactec team for delivering (once again) two beautiful, reliable, Made in the USA machines!

This customer needed a customized machine and knew that Mactec Packaging Technologies was the place to go!

Do you have a thermoforming, pouching, or fill/seal process that requires a non-standard solution? Reach out to your local Sales Manager or visit the Contact Us Page on our website!

#MactecPackagingTechnologies #PackagingEquipment #UnitDoseFilling

Mactec Packaging Technologies’ busy show season is coming to a close, but we have one more stop in Las Vegas that we are ready to see you at! Join as booth 7651 during MJ Bizcon 2022 and speak with our experts on how we can support your unit dose packaging equipment needs. The booth will be showcasing our Nano-60X thermoforming machine which is great for gummy production among other applications. We are still running special show pricing on the Nano-60X, so stop by the booth this week or contact us through our webpage to take advantage of this special offer!

Pack Expo is now complete, thanks to all who stopped by our booth to visit. It was a great show!

Now on to the next show. Come visit us at booth #4186 during SupplySide West at the Mandalay Bay Convention Center in Las Vegas. We look forward to discussing your blister, pouching and fill/seal needs!